21 Degrees Heating Ltd specialise in the design, manufacture, supply, installation, testing and commissioning of industrial and commercial heating services. We offer a full in-house design service, and run our own pipe fabrication service, giving clients greater certainty on project delivery than the industry norm. Our commitment to delivering first class services is reflected in a high level of repeat business.

21 Degrees Heating Ltd aim to provide a professional service to all our clients within the commercial M&E heating services industry.

We pride ourselves upon unprecedented high levels of quality and individual needs through concept to completion.

As 21 Degrees Heating Ltd has grown over the years, we have incorporated further services to our portfolio.

We now offer full design Electrical and BMS services, District Heating Services, Air Source Heat Pumps (ASHP), AC and Ventilation along with our in-house ground works services team.

In addition to the above services, we also supply and service a number of our own temporary boiler plants, ranging from 100KW to 2MW to provide emergency heating and hot water.

At 21 Degrees Heating Ltd we can work with you to meet your requirements through planned preventative maintenance and condition monitoring/reporting. We can consult on project management, design, and space planning.

We pride ourselves on having staff members who have been with the company since its foundation in 2004. We operate with a staff of 20+.

Our main area of work is within the social housing sector, large commercial refurbishment and commercial new build where we carry out the installs of plant rooms, heating, gas and cold water distribution and in-flat installation of pipework, radiators, boilers and HIU’s.

We have carried out numerous projects over the years here is an example of some of them:

Tower Bridge

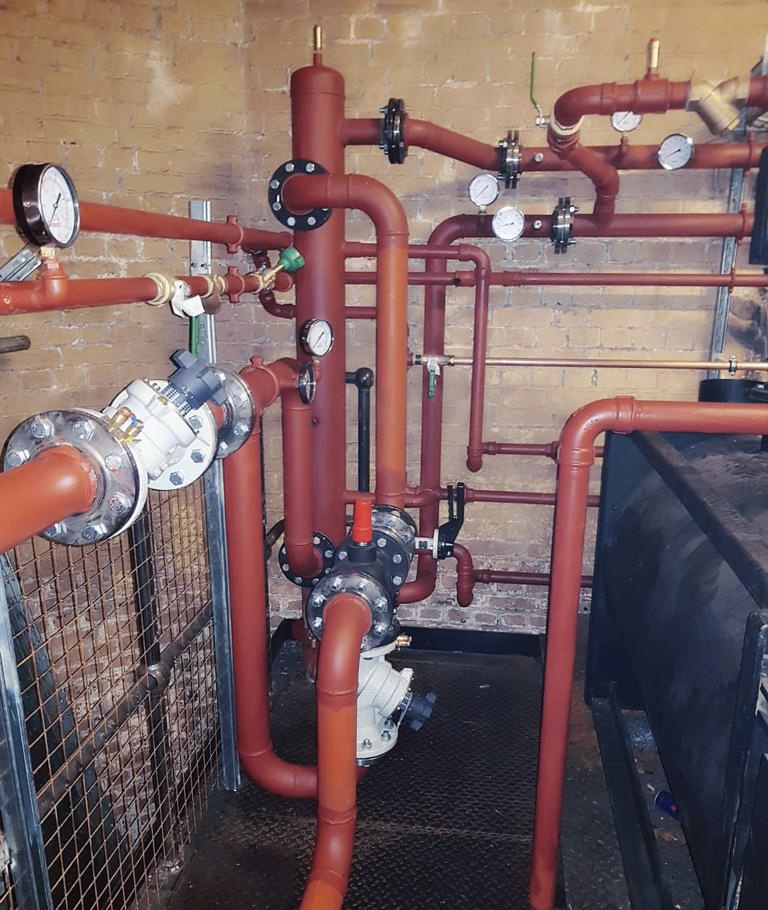

Installation of 2 new commercial boiler rooms and distribution pipework. Renewal of gas pipework. Project value £800000.

This project involved installing new structural steelwork to extend the existing plantrooms within the 2 main piers. Remove the redundant plant and install a completely new boiler plant onto the new steelwork platform. From there we installed new distribution pipework up to the 2 public viewing walkways to feed the existing radiators and new high level space heating. The existing gas supply to the southwest tower boiler room was leaking and had to be replaced. This involved running a new pipe from the existing gas metre room located on Shad Thames beneath the bridge. Through the gift shop and up onto the Tower Bridge Approach foot path within a duct. All of this was carried out during the height of the tourist season. This was a complex project as we had to work around the public and staff and busy traffic that crosses the bridge every day. Planning and preparation were key to the success of this project which was completed on time.

Kingston Hill Campus

Installation of new plantrooms to various blocks. Distribution of heating and hot water pipework and ductwork to 463 student accommodation rooms. Project Value £1500000

This project was broken down into separate student blocks. Students were moved out of each block then demolition of internal walls etc was carried out. 21 Degrees Heating then installed new heating, hot water and cold-water distribution pipework from satellite plantrooms also installed by us to each new student room. New bathroom pods were installed by other contractors and 21 Degrees connected to these and installed new ventilation. The satellite plantrooms were in the loft space of the block with a Plate Heat Exchanger and Hot Water Calorifiers. The main plantroom that fed the whole site consisted of 6 x 250 kw boilers, plate heat exchanger and distribution pumps. 21 Degrees installed a new gas supply to the building from the existing supply 500m away. To keep the smooth running of the site this was done using directional drilling. A method whereby a specialist rig is set up and drills the whole 500m length approximately 1m depth then pulls the new MDPE pipe back through the drilled hole. After the pipe is installed, we send a foam pig through it under pressure to make sure no dirt or debris contaminated the pipe. Finally, a remote-controlled camera is sent the length of the pipe to check all is clear

Seething Wells

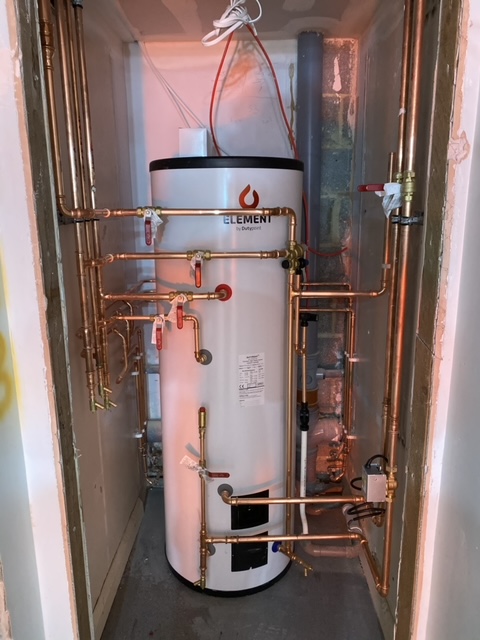

Installation of new pipework to student accommodation blocks, site wide distribution of gas network. Work to Heritage Buildings installing Air Source Heat Pumps. Project value £1000000

Very similar to the Kingston Hill project except the blocks are smaller and run of heat only domestic type boilers. We installed new hot water cylinders and heating distribution to rooms and communal areas. Outside the blocks the gas network was upgraded as well as new cold-water supply to all the blocks. We installed a new Air Source Heat pump to feed one of the Victorian built Heritage Buildings to supply the heating and hot water primary pipework.

Bow Street Magistrates Court refurbishment to a new hotel

Installation of a new plantroom and distribution of hot water, cold water and chilled water. Gas pipework distribution to boiler room and commercial kitchens. Project value £750000

This was another complex project as we had to work alongside multiple trades in a Heritage Building. The work involved a new 6” in 8” gas distribution pipe within the building to supply the new level 3 plantroom and 3 commercial kitchens. 21 Degrees Heating carried out the installation of the new plantroom and the distribution of the associated pipework to the new hotel rooms.

St Martins Hospital NHS Trust

Refurbishment of 3 boiler rooms in 3 separate blocks including new BMS panels. Project value £400000

These plantrooms fed varying size blocks to the hospital in Canterbury. We carried out complete renewal of each plantroom from strip out to commissioning and hand over consisting of new boilers, plate heat exchangers, pumps and pipework and new controls.

London Borough of Southwark. Brimmington Estate

Installation of new district heating mains from a centralised boiler house to over 1000 properties. Project value £1200000

21 Degrees carried out the civils works installation of 2km of flow and return pre-insulated steel pipework. This involved the excavation around the estate working in close proximity to the public, as well as organising road closures and traffic management with Southwark Council. All the pipework installed was carried out in accordance with Class 1 welding and all welds were tested and numbered before been closed up using the specialist Mittel method of jointing.

City of London. Middlesex and York Way Estates

21 Degrees Heating installed new plantrooms to each of these blocks consisting of new boilers, buffer vessels, plate heat exchangers, pumps and pipework with a project value £1500000. At the same time, we installed new distribution heating pipework from the plantrooms and new cold water pipework to the various blocks terminating outside each flat. After full pressure testing and insulation these were handed over to the teams that carried out the in flat installation of new HIU’s and radiators

Aylesbury Estate Southwark

The Aylesbury Estate, situated in Southwark London, comprises a central energy centre feeding an array of satellite plant rooms which in turn serve the blocks heating and hot water needs of the entire estate valued at £1100000. The refurbishment works undertaken by 21 Degrees Heating comprised of a complete refurbishment of the energy centre itself as well as nine of the satellite plant rooms.

The centralised energy centre is comprised of three 1500kw (1.5 megawatts) boilers providing a total of 4.5 megawatts of heat. These boilers leave the plant room via x 2 plate heat exchangers and are distributed via pump sets for each leg of the estate. 21 Degrees carried out a complete strip out and replacement of all plant, pipework (up to 24 inch) and insulation within the energy centre.

The satellite plant rooms fed from the energy centre are comprised of a secondary heat exchanger, HWS Calorifiers and circulating pumps out to the blocks. All interconnecting pipework, valves, ancillaries, filters and insulation were replaced also. Once complete, the energy centre and subsequent satellite plant rooms were commissioned and set to work.